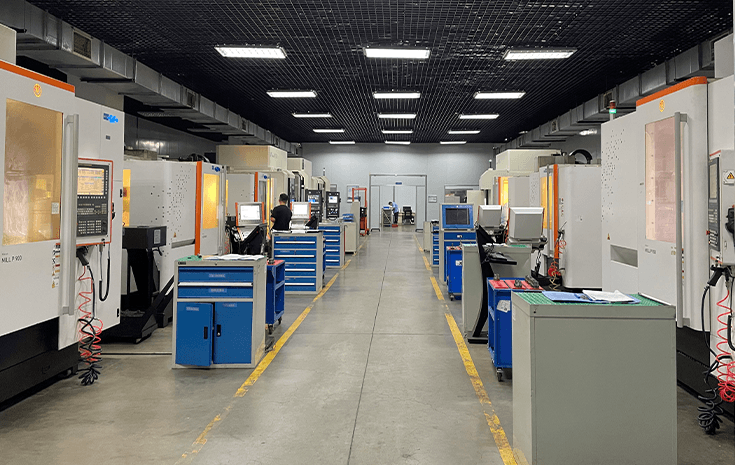

Recently have over 5000 square meters plant area and over 200 technicians in various mold processing positions, with mainly business on producing plastic molds for laptops, automobiles, mobile phones and office accessory; on hardware, we have over 100 professional equipment for precision mold processing with mold manufacturing precision tolerance within 0.002mm-0.005mm according to actual needs, and the products injection precision tolerance through our molds within 0.015mm-0.03mm. In addition, we use high-standard grinding and polishing to make mold interior surface as smooth as mirror to prevent burrs from injection molding. Through the comprehensive implementation of automation, digitization, cloud computing and mega data systems, we have significantly reduced the process time from mold development to delivery. At present, our customers can start production within two months from they delivery draw to us.

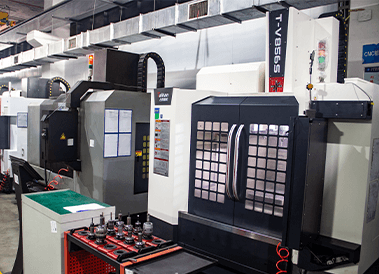

In mold design, we extensively use industry software and use artificial intelligence (AI) and digital twins methods simulation calculation the process and structure for the best potential solution. When optimized solution have generated, we will use video conferences or dispatch our experts to the scene to explain in detail to customers. We use mold copper for flexible adjustment and optimization in mold development, then we currently choose mold steel from Daido Steel to offer best potential quality and life-cycle in mold manufacturing, which provides lower unit cost and higher quality to customers. We have also established a strict sewage purification and discharge system and strictly implemented it to protect our own homes and working environment.

We pay close attention to team building. Hence we have set comprehensive training to allow newcomers to fully integrate into the Yuhai family in a short period, and encourage employees to participate further education to increase their personal career competitiveness and income. Through implement software simulation, computerized numerical control (CNC) lathe and other automation equipment, we have greatly reduced the physical labor intensity of personnel to ensure employees can maintain vigor, persist in creative work and enjoy their lives.